The Mesh PropertyManager lets you mesh models for solid, shell, and mixed mesh studies. The terms "compatible" and "incompatible" mesh refer to the type of mesh continuity on touching geometrical entities that belong to different bodies. Shell elements are naturally suitable for modeling thin parts (sheet metals), and beams and trusses are suitable for modeling structural members.

Solid elements are naturally suitable for bulky models. A mesh consists of one type of elements unless the mixed mesh type is specified. Meshing generates 3D tetrahedral solid elements, 2D triangular shell elements, and 1D beam elements. For a more accurate solution, a smaller element size may be required. In the early stages of design analysis where approximate results may suffice, you can specify a larger element size for a faster solution. The size of the generated mesh (number of nodes and elements) depends on the geometry and dimensions of the model, element size, mesh tolerance, mesh control, and contact specifications.

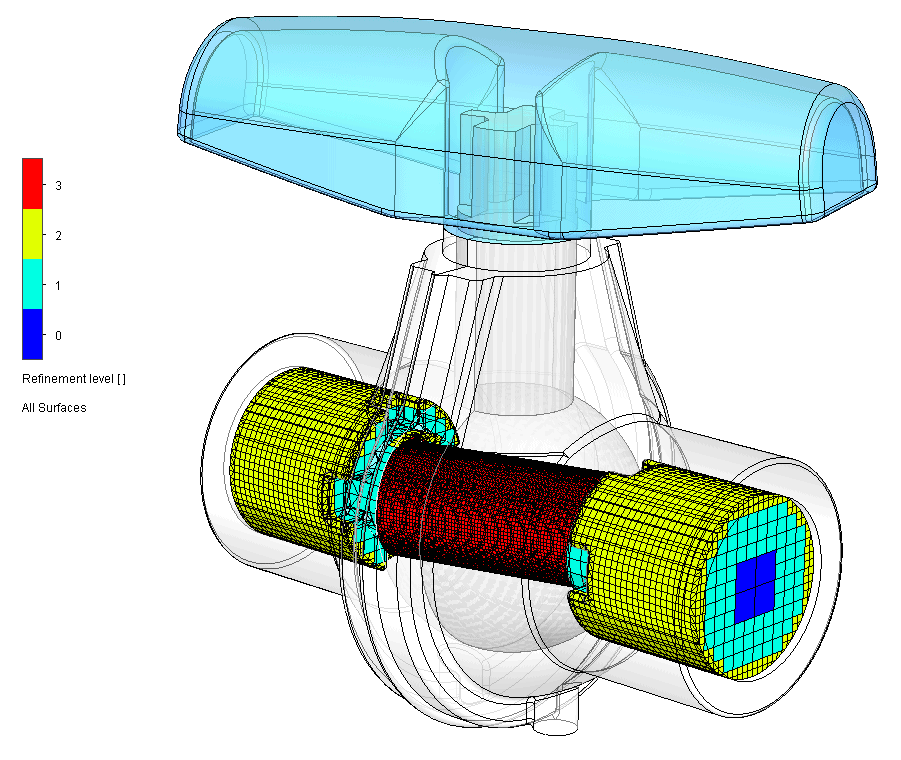

#Solidworks flow simulation mesh software

The software estimates a global element size for the model taking into consideration its volume, surface area, and other geometric details. Mesh control lets you specify different sizes of elements for components, faces, edges, and vertices. The automatic mesher in the software generates a mesh based on a global element size, tolerance, and local mesh control specifications. Meshing is a very crucial step in design analysis. The Finite Element Method (FEM) predicts the behavior of the model by combining the information obtained from all elements making up the model. Finite element analysis programs look at the model as a network of discrete interconnected elements. Then, the program subdivides the model into small pieces of simple shapes (elements) connected at common points (nodes). The process starts with the creation of a geometric model. Lead-in comments are encouraged to provide context to the readers.Finite Element Analysis (FEA) provides a reliable numerical technique for analyzing engineering designs. Completed projects, destructive test results, and unique machinery and hardware are all acceptable and encouraged. Images and videos related to engineering are acceptable, provided they are relevant to engineering. Engineers should help each other to make the world a safer and better place.

#Solidworks flow simulation mesh how to

Questions about current engineering projects you are working on, how to interpret codes and standards, and industry practices are all encouraged. R/engineering is a forum for engineering professionals to share information, knowledge, experience related to the principles & practices of all types of engineering: civil, structural, mechanical, electrical, aerospace, chemical, computer, environmental, etc. No low-effort one-liner comments, memes, or off-topic replies. Racism, sexism, or any other form of bigotry will not be tolerated.īe substantive. Overly insulting or crass comments will be removed. You are allowed one submission, and you must be active in the comments to answer any questions. You can read about why this policy exists here.Ĭrowdfunding: Must be relevant to engineering and submitted as a self-post (not a link).

No posts about the 9/11 terrorist attacks. All sources are subject to moderator evaluation. This includes YouTube channels, blogs, etc. For assistance with resumes, try /r/EngineeringResumes.Job postings must go into the Quarterly Hiring Thread.No questions on "how something works" - try r/AskEngineers.Īll workplace topics and questions asking for career advice must go into the Weekly Career Discussion Thread. NOTE: Asking for help on homework will result in an instant ban. No questions related to university, school, major selection, GPA, coursework, etc. If you see any post or comment that violates these rules, please report it so the moderators can respond in a timely manner.

0 kommentar(er)

0 kommentar(er)